About Us

We are an ISO 9001 Certified & reputed manufacturer of Industrial Pins with expertise gleaned over 40 years. We manufacturers these pins according to various standards namely ISO, IS, DIN, BS and also as per customers requirements.

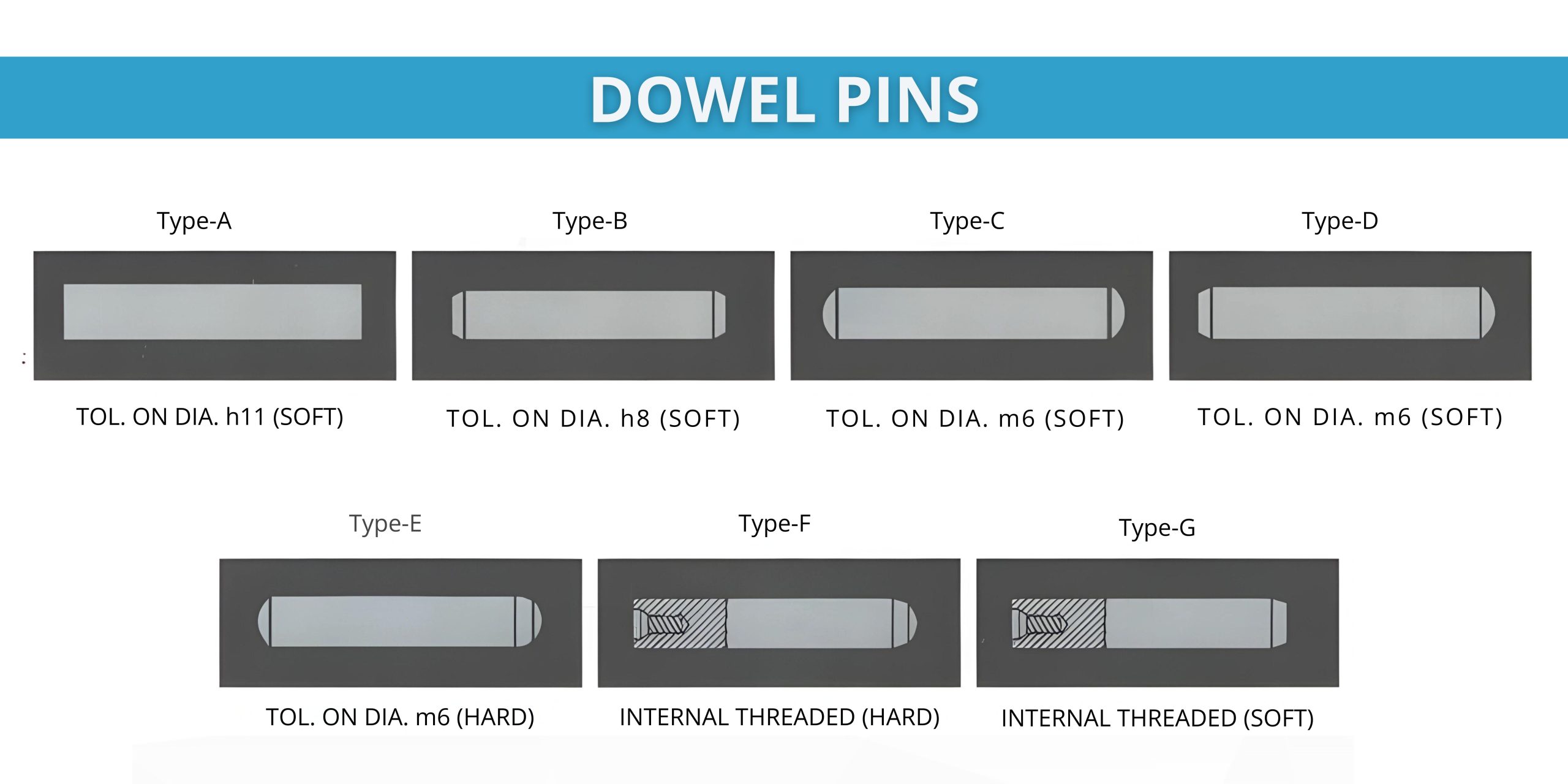

Cylindrical (Dowel) or Parallel Pins are used either to retain parts in a fixed position or to preserve alignment. A few of them are illustrated above. Type A, B, C, & D are unhardened from Free cutting or low and medium Carbon steel material. Our manufacturing range for Cylindrical (Dowel) Pins is 1.5 mm to 25 mm in diameter and 5mm to 150mm in length. Type E is hardened from alloy steel material.

Internal Threaded Cylindrical (Dowel) Pin are for easy extraction, from blind holes. They are manufactured in soft or unhardened condition (Type G) from Free cutting Carbon steel material. Hardened Pins (Type F) are manufactured from alloy steel or as per customers requirement. An air vent is usually provided.

Applications – These are designed to achieve maximum holding power in assemblies where parts must be accurately positioned and held in absolute relations to one another.

No longer are dowels put in wherever there happens to be available space; they serve definite and important functions in holding parts in alignment by absorbing side pressures and lateral thrusts, at the same time facilitating quick disassembly re-assembly in their exact relationship.

In die making and precision tool design, where tolerances often split thousandths of an inch, it is critical that correct doweling methods and the right dowel pins be used. It is important to bear in mind that dowel pins should be employed for locating purposes and never to replace a screw for fastening purposes.

Widely utilized as shafts, hinges, wrist pins, stops, guide pins, and plug gauges in a variety of production processes. Additionally utilized as roller bearings in casters and truck wheels, as well as position locators on indexing machines, aligning parts, feeler gauges in assembly work, valves and valve plungers on hydraulic equipment, fasteners for laminated sections and machine parts, and valves on hydraulic equipment.

Panama Enterprises offers dowel pins at affordable prices. The main purpose of our dowel pins is precise positioning.

We are an ISO 9001 Certified & reputed manufacturer of Industrial Pins with expertise gleaned over 40 years. We manufacturers these pins according to various standards namely ISO, IS, DIN, BS and also as per customers requirements.