About Us

We are an ISO 9001 Certified & reputed manufacturer of Industrial Pins with expertise gleaned over 40 years. We manufacturers these pins according to various standards namely ISO, IS, DIN, BS and also as per customers requirements.

Grooved Pins are parallel pins with three equi-spaced longitudinal grooves. They are rolled or pressed into the cylindrical body to deform the pin stock outward within controlled limits. When this pin is forced into a drilled hole of proper diameter, a locking fit is obtained. Only a straight drilling hole is required and no reaming is needed.

Grooved Pins or Notch Pins are manufactured from C-40 (EN-8) material. They are supplied in soft condition and natural finish unless otherwise specified by the customer. Our manufacturing range for Grooved pins is from 2 to 16 mm in diameter and 5 to 150 mm in length.

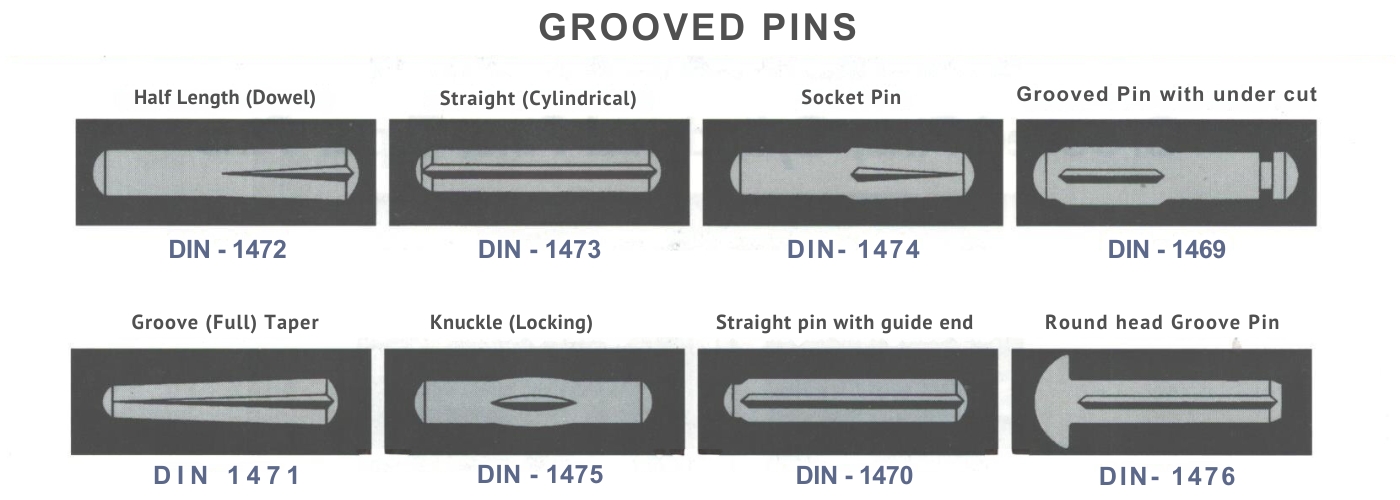

Types of Grooved Pins

We are an ISO 9001 Certified & reputed manufacturer of Industrial Pins with expertise gleaned over 40 years. We manufacturers these pins according to various standards namely ISO, IS, DIN, BS and also as per customers requirements.